Solutions

Delivering Superior Solutions

We lead the market with the most comprehensive portfolio of paper release liners, film release liners and engineered film solutions and collaborate with customers around the world

Our product solutions are customized to your application and processing requirements, with options for added differentiation through printing and embossing

Paper Release Liner

We offer the industry’s most comprehensive portfolio of direct coated and poly-coated paper release liners:

- Direct Coated Solutions: release liners coated with silicone on one or both sides

- Poly-Coated Solutions: release liners coated with poly and silicone on one or both sides

Available Silicone Coating Systems:

- Emulsion

- Solvent-Based

- Solvent Free

Curing Systems

- Electron Beam (EB)

- Thermal

- Ultraviolet (UV)

Available Base Papers:

- Clay Coated Kraft (CCK) Paper

- Glassine (GLS)

- Super Calendered Kraft (SCK) Paper

- Machine Finished (MF)

- Machine Glazed (MG) Kraft Paper

All our paper suppliers are FSC® certified and we can provide you with certified material upon request.

We tailor release force, grammage, coating weight, width, and packaging to your product and processing requirements, with added support for various types of printing

Film Release Liner

We offer the industry’s most comprehensive portfolio of direct coated and poly-coated film release liners:

- Direct Coated Solutions: release liners coated with silicone on one or both sides

- Poly-Coated Solutions: release liners coated with poly and silicone on one or both sides

Available Silicone Coating Systems:

- Emulsion

- Solvent-Based

- Solvent Free

Curing Systems

- Electron Beam (EB)

- Thermal

- Ultraviolet (UV)

Available Base Films:

- Low Density Polyethylene (LDPE)

- High Density Polyethylene (HDPE)

- Polypropylene (PP)

- Amorphous Polyester (APET)

- Ethyl Vinylene Alcohol Copolymer (EVOH)

- Polyamide (PA)

- Polystyrene (PS)

- Films based on ISCC PLUS certified raw material

- Substrates with recycled material content

- Biopolymer and bio-degradable options

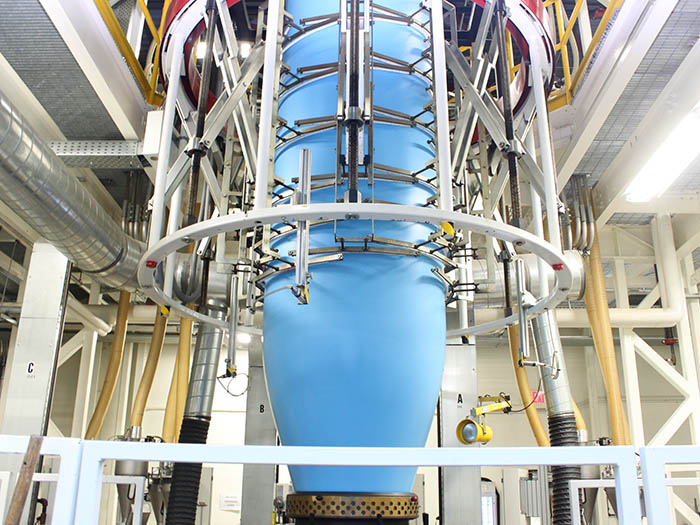

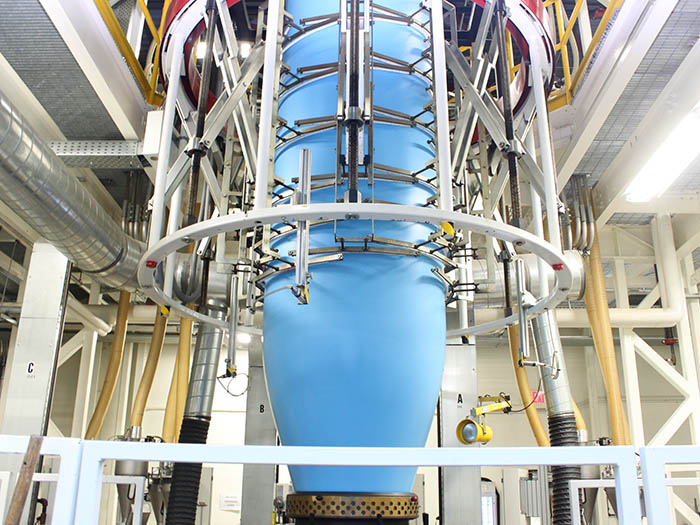

We have extensive in-house blown and cast film extrusion capabilities, and customize release force, coating weight, width, and packaging based on your individual needs

A variety of embossing and printing options are also available to provide further value and differentiation

Engineered Films

We offer a broad portfolio of uncoated engineered functional film solutions:

- Protective Film Solutions: single or multilayer film solutions to protect end-products

- Barrier Film Solutions: multilayer film solutions with superior barrier functionality

- Membranes: permeable film constructions

Available Substrates:

- Low Density Polyethylene (LDPE)

- High Density Polyethylene (HDPE)

- Polypropylene (PP)

- Amorphous Polyester (APET)

- Ethyl Vinylene Alcohol Copolymer (EVOH)

- Polyamide (PA)

- Polystyrene (PS)

- Films based on ISCC PLUS certified raw material

- Substrates with recycled material content

- Bio-degradable and bio-based options

Our blown and cast film extrusion lines allow us to create sophisticated solutions with constructions of up to 9 layers, including mono-material film designs

Additionally, we offer a wide range of customization options for your specific product and processing needs, including printing and embossing

Let our technical experts guide you through an unlimited world of possibilities, including sustainable options, to find the solution that best meets your market, application, and individual needs

Solution Development

Whether adjusting liner performance to better match your product needs or engineering all-new market-defining solutions, we create lasting value through customization and innovation

Customized Solutions

From fine-tuned mechanical properties to special functions, custom multi-color print designs, individual widths or special packaging requirements – we shape our solutions to your needs:

- Mechanical Performance: Modify key properties such as mechanical strength, thermal stability, and stiffness to match your product and processing concepts

- Adjustable Release: Release ranges from premium easy to tight are adjusted to your requirements, with the option of differential release for two-side coated liners

- Additional Functions: Create further protection and value through options such as moisture, oil, and gas barriers, permanent and self-discharging antistatic effects, or antimicrobial additives

- Optics: Make your product unique by choosing from colored base films and papers or adding your custom print design

- Sustainability: Choose from our portfolio of certified sustainable and renewable materials, or use our expertise to improve the recyclability of the end product

Joint Innovations

Work with Loparex product, market and technology experts to develop your next great innovation. We leverage and share our expertise to jointly develop solutions with unique and sustainable competitive advantages:

- Results Driven Approach: Our development process provides structure and flexibility needed to ensure rapid iterations and shortest time-to-market

- Diverse Expert Teams: Our global development teams consist of chemists, physicists, material scientists, process engineers, and patent/IP specialists, supported by subject matter experts from across the company

- Dedicated R&D Facilities: Loparex maintains multiple pilot lines for a rapid assessment of process and product characteristics, as well as extensive lab facilities for customized analytical procedures and product quality testing

- Partners: We collaborate with our broad network of suppliers, universities, associations and market experts to develop leading solutions that make the difference

Service Portfolio

Local support, responsive contacts, and expertise you can trust — Loparex is committed to providing a world-class customer experience and supporting your business where it matters most

Dedicated Local Support

Across the world, our teams are dedicated to helping you.

As a Loparex customer, designated regional contacts are available to address any order, product, or process issues you may encounter. You can find contact detail of all our global sites here

Technical Expert Consultation

The technical experience you need — right at your doorstep.

The Loparex Field Technical Service (FTS) team brings industry-leading application and manufacturing experience directly to your production lines, providing on-site guidance where it’s needed the most

Regulatory Compliance Services

We help you navigate local and international regulations.

Ensuring compliance can be a complex and challenging process. Take advantage of our extensive knowledge of market and industry-specific regulatory requirements to bring your products to market faster and avoid costly missteps

Our Markets

Our experts understand the diverse challenges from all relevant end-applications

Tapes »

Building &

Construction »

Health Care »

Graphics »

Label »

Hygiene »

Composites »

Automotive »

Electronics »

Renewable

Energy »

Shipping &

Mailing »

Other

Applications »

Don't see your market? Contact our technical experts to discuss your needs in more detail

Contact Us

Interested in our solutions or need support?